Welcome to our guide on structural steel fabrication! If you’re curious about how structural steel components are manufactured and assembled, you’re in the right place. We’ll explore the fascinating world of steel fabrication, covering everything from the fabrication process to its applications, benefits, and safety considerations. Whether you’re a novice in the field or an industry expert, there’s something valuable for everyone to learn about structural steel fabrication.

Structural steel fabrication involves the process of transforming raw steel materials into predefined shapes and sizes to create structural components used in construction projects.

Here's what you need to know about the key aspects of steel fabrication:

Steel Manufacturing:

- Steel manufacturing begins with the production of raw steel materials, which are typically derived from iron ore through a process called smelting.

- The raw steel is then processed in steel mills where it undergoes refining and shaping to meet specific quality standards and specifications.

Steel Fabrication Process:

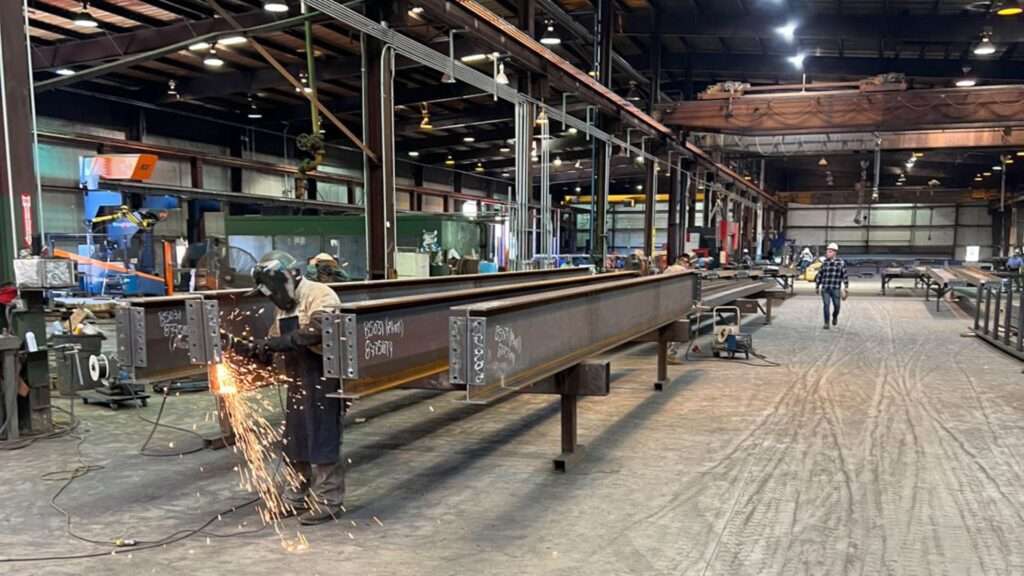

- The steel fabrication process involves several stages, including cutting, bending, shaping, welding, and assembly.

- Advanced technologies such as computer-aided design (CAD) and computer numerical control (CNC) machining are often utilized to ensure precision and efficiency in fabrication.

Structural Steel Production:

- Structural steel production focuses on manufacturing components such as beams, columns, trusses, and frames used in building construction.

- These components are fabricated to precise dimensions and tolerances to ensure structural integrity and stability in the final structure.

Steel Fabrication Techniques:

- Various fabrication techniques are employed depending on the requirements of the project and the complexity of the structural components.

- Common techniques include cutting (using saws, shears, or plasma torches), bending (using press brakes or rolling machines), welding (using arc welding or gas welding), and assembly (bolting or riveting).

Structural Steel Applications and Benefits:

Structural steel fabrication finds widespread use in a variety of construction projects due to its numerous advantages:

- Versatility: Structural steel can be fabricated into various shapes and sizes, making it suitable for a wide range of applications in residential, commercial, and industrial construction.

- Strength and Durability: Steel offers exceptional strength-to-weight ratio and durability, making it an ideal choice for supporting heavy loads and withstanding environmental factors such as wind and seismic forces.

- Speed of Construction: Steel fabrication allows for faster construction compared to traditional building materials, resulting in shorter project timelines and cost savings.

- Design Flexibility: Steel’s inherent properties allow for greater design flexibility, enabling architects and engineers to create innovative and aesthetically pleasing structures.

- Sustainability: Steel is a highly sustainable building material that is recyclable and energy-efficient, contributing to green building practices and environmental conservation.

Safety Considerations in Steel Fabrication:

While steel fabrication offers numerous benefits, it also comes with inherent safety risks that must be addressed:

- Worker Safety: Safety measures such as personal protective equipment (PPE), training programs, and adherence to safety regulations are essential to prevent accidents and injuries during fabrication.

- Fire Safety: Proper fire prevention and suppression measures should be implemented to minimize the risk of fire hazards in steel fabrication facilities.

- Material Handling: Safe handling and storage practices are crucial to prevent accidents related to material handling, lifting, and transportation of steel components.

Structural steel fabrication plays a vital role in the construction industry, providing the framework for buildings, bridges, and infrastructure projects around the world. From its manufacturing process to its applications, benefits, and safety considerations, steel fabrication encompasses a diverse range of topics that are essential for understanding the complexities of modern construction. By mastering the fundamentals of structural steel fabrication, engineers, architects, and construction professionals can contribute to the creation of safer, more efficient, and sustainable built environments for generations to come.