How To Choose the Right Welding Metal Fabrication Services Company

A company’s reputation and image are primarily based on the caliber of its goods and services. Therefore, a brand can be greatly impacted by the caliber and dependability of the work generated by its welding metal fabrication partner in a number of ways, ranging from the usefulness of the product to the frequency of on-time order fulfillment.

Selecting the right metal fabrication firm can be difficult, particularly if you need highly specialized services. This post will guide you through the things to look for when selecting the best bespoke welding metal fabrication services company.

The process of combining metal components to make structures, goods, or machinery is known as welding metal fabrication. These services cover a wide range of material needs from aluminum to stainless steel in various industries. The level of quality, durability, and efficiency of the finished product are determined by the experience of a fabrication company.

Key Considerations for Choosing a Welding Metal Fabrication Partner

1. Expertise and Experience

Find a fabrication partner with proven expertise and experience to ensure a successful partnership. Look for a company that has handled similar projects, understands various materials, industry standards, and compliance requirements. Their extensive knowledge can offer tailored solutions for your needs

2. Technology and Equipment

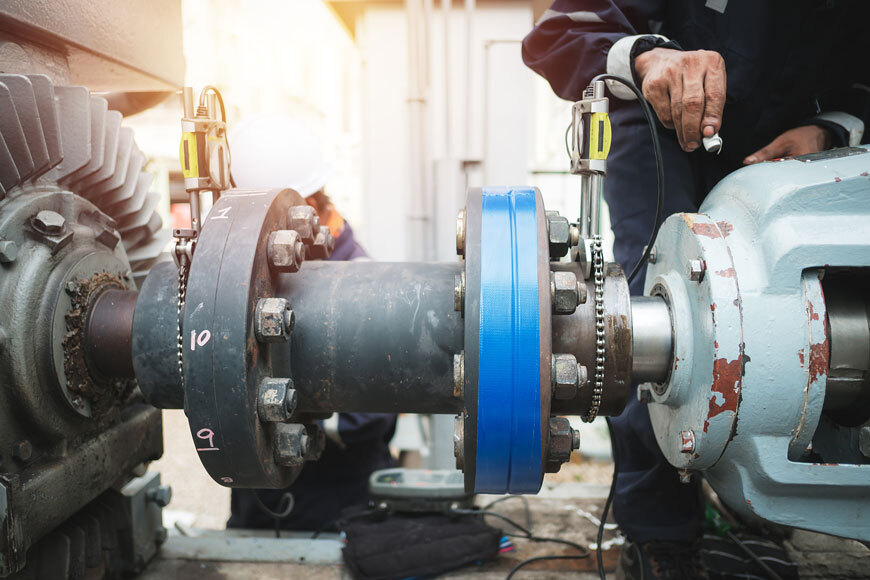

The accuracy and effectiveness of the fabrication process are directly impacted by the caliber of tools and technologies a fabrication partner uses. Make sure the partner uses cutting-edge equipment and tools that can handle a variety of fabrication needs. Investing in contemporary equipment, such as CNC machines and cutting-edge welding technologies, shows a dedication to producing outcomes of the highest caliber.

3. Quality Assurance and Certifications

In order to guarantee accuracy, uniformity, and adherence to industry standards, quality assurance is crucial in the metal fabrication process. Seek out a partner with the necessary credentials, such as AWS certification for welding procedures and ISO 9001 certification for quality management systems. These accreditations attest to the partner’s dedication to upholding the highest performance and quality standards.

4. Customization and Flexibility

Every project comes with its own unique challenges and requirements. Select a manufacturing partner who can adapt and customize to meet your unique requirements. The effectiveness and success of your project can be increased by a partner who is prepared to modify and customize their services to fit your needs, whether those alterations involve custom fabrication solutions or adjustments to pre-existing designs.

5. Communication and Collaboration

Effective collaboration during fabrication hinges on clear communication. Choose a partner who is responsive, transparent, and open in their communication. Clear and timely communication fosters confidence and ensures alignment among stakeholders, from initial discussions to project updates and post-delivery support.

6. Cost-Effectiveness and Value

Cost is obviously an issue, but when choosing a fabrication partner, value must take precedence above price. Examine the partner’s whole value proposition while taking quality, dependability, and long-term support into account. It is worthwhile to engage a partner who can provide outstanding value through prompt delivery, high-quality craftsmanship, and satisfied customers.

7. Reputation and References

The standing of a partner says a lot about their dependability and integrity. Examine their standing in the field, go through customer reviews, and ask previous clients for recommendations. Positive feedback and endorsements are signs of a partner’s dedication to quality work and client pleasure. Take into account other elements as well, such longevity in the field and affiliations with respectable institutions.

8. Capacity and Scalability

Take into account the partner’s ability to handle projects of different sizes and complexity, as well as their scalability. Make sure your partner has the tools and resources necessary to fulfill your needs, regardless of the size of the project—whether it’s a large-scale production run or a small-scale prototype. Examine their lead times, scalability, and production capacity to ensure that they can handle future expansion.

Choose WeldIT Services for Your Welding Fabrication Needs

Since 2003, WeldIT Sheet Metal has offered top-notch fabrication services! We can manage mid-volume production runs and provide prototyping services for metal fabrication. We also have a wide range of automatic and manual welding, finishing, and metal forming technologies at our disposal.

Steel, aluminum, copper, brass, stainless steel, and other materials are among the metals in which we specialize. Get in touch with us now or request a quotation for further details!