Transforming Welding Safety with Custom Print Fabric

In the ever-evolving landscape of welding, where safety and efficiency stand as pillars of paramount importance, a revolutionary solution has emerged to redefine the traditional norms – Custom Print Fabric. This specialized and innovative approach not only enhances safety measures but also introduces a new dimension of personalization to the tools and equipment within the welding industry.

Welding Curtains: A Fusion of Functionality and Branding

At the forefront of this innovation is the application of custom-printed fabrics in the creation of welding curtains or screens. Crafted with precision from these specialized fabrics, these curtains transcend their practical function as mere barriers to contain sparks, debris, and intense welding light. What sets them apart is the ability to personalize these curtains with safety instructions, company logos, or specific color codes, adding a layer of communication and brand representation to the very fabric of the workspace.

Welding Apparel: Protection Meets Personalization

Another arena where custom print fabric leaves an indelible mark is in welding apparel. Welders, often clad in protective clothing made from specialized fabrics, now have the opportunity to elevate their gear with customized prints. Whether it’s a unique design, corporate branding, or essential safety information integrated into the fabric, these customized welding jackets, aprons, and gear not only offer unparalleled protection but also contribute to cultivating a professional and branded work environment.

Equipment Covers: Shielding with Style

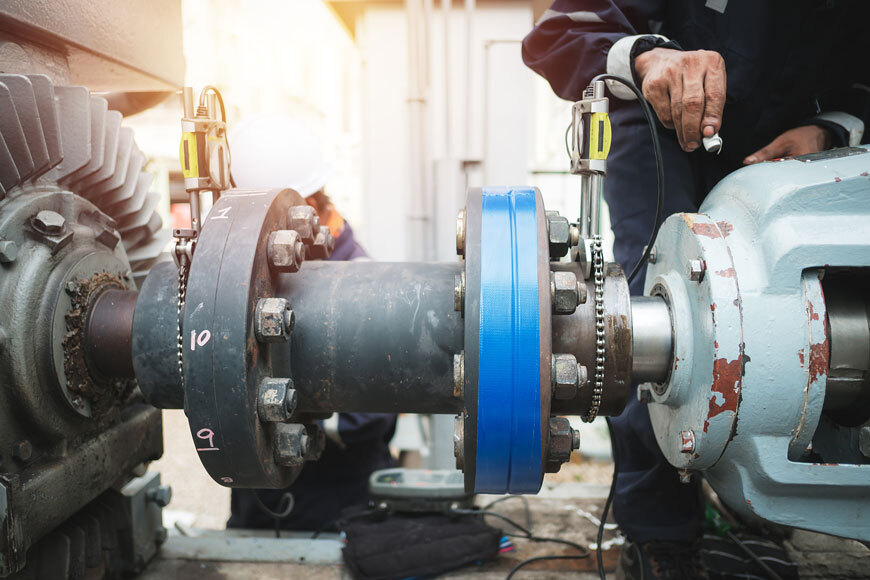

Preserving the longevity and functionality of welding machinery is a critical aspect of the industry. Enter custom-printed fabrics for equipment covers. Companies now have the ability not only to shield their equipment from dust and debris but also to display branding elements and safety information on these covers, creating a cohesive and visually appealing workspace. The fusion of functionality and aesthetics is evident as these covers become an integral part of the welding environment.

Safety Signage: Dynamic Communication in Fabric Form

Safety signage, a cornerstone of any welding workspace, undergoes a metamorphosis with custom print fabric. Banners and signs made from these innovative fabrics provide a dynamic platform for conveying important safety instructions, warnings, or other critical information. This ensures that safety guidelines are not just followed but are prominently displayed, contributing significantly to a secure working environment.

Welding Tents and Enclosures: Portable Personalization

In applications where controlled environments are imperative, custom-printed fabrics find their place in the creation of welding tents or enclosures. These portable structures, designed with personalized prints, not only establish a controlled workspace but also provide an opportunity for branding and communication within the welding site. The flexibility and adaptability of these structures redefine how welding environments are set up and managed.

The Evolution of Custom Print Fabric in Welding Applications

As the demand for customization grows, the applications of custom print fabric in welding continue to evolve. One area where this innovation is making significant strides is in the development of heat-resistant and flame-retardant fabrics. These fabrics, designed to withstand the extreme conditions of welding environments, ensure that both functionality and safety are at the forefront.

The incorporation of advanced technologies, such as RFID tags or QR codes, into custom-printed fabrics is another exciting development. This allows for real-time tracking of equipment, enhanced safety protocols, and streamlined inventory management. Welding companies can leverage these smart fabrics to optimize their operations, improve traceability, and enhance overall efficiency.

Future Prospects and Challenges

Looking ahead, the prospects for custom print fabric in welding seem promising. The ability to integrate technology, ensure sustainability, and provide a customized user experience positions these fabrics as integral components in the future of welding safety.

However, challenges exist, particularly in ensuring that these fabrics meet and exceed safety standards. Rigorous testing and certification processes are essential to guarantee that custom-printed fabrics maintain their protective qualities under various welding conditions. This emphasis on safety is crucial to building trust in the industry and encouraging widespread adoption.

The cost-effectiveness of custom-printed fabrics remains a consideration. While the benefits are evident, companies must weigh the initial investment against long-term gains in safety, efficiency, and branding. As technology advances and production processes become more streamlined, it is anticipated that the cost barrier will gradually decrease, making custom print fabric a more accessible choice for a broader range of welding applications.