Top 8 Reasons Why Rig Welding Services Are Your Best Choice

Tailored Precision with Custom Welding Rigs

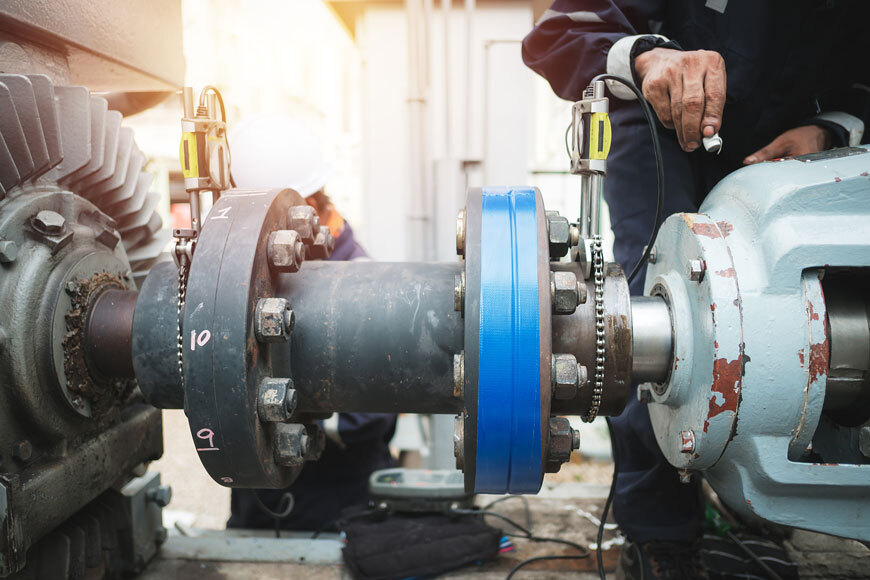

Custom welding rigs and tailored precision are the pinnacle of what rig welding services have to offer the welding industry. These services, in contrast to one-size-fits-all methods, make use of specially made welding rigs that are painstakingly tailored to each project’s unique needs.

These rigs are created with precision and attention to detail, allowing welders to attain a level of accuracy that goes beyond conventional procedures. Because these rigs are custom-made, welding operations are tackled with the exact tools required for the job, producing faultless welds and enhancing the general effectiveness and success of a variety of welding projects.

Mobility and Flexibility

The range of welding options is redefined by the mobility and flexibility provided by rig welding services. These services can easily access and operate in remote regions and construction sites because they are outfitted with specialized welding rigs. Because of their outstanding mobility, welding services are not restricted to a single place, which makes them perfect for projects requiring on-site assistance in a variety of geographic situations.

Rig welding services are highly advantageous for customers looking for welding solutions that go beyond the constraints of conventional, stationary welding setups because of their adaptability to various settings, which allows them to serve a broad range of industries and project types.

Specialized Expertise in Welding Rigs

Specialized knowledge of managing welding rigs is the cornerstone of rig welding services. These services offer more than just cutting-edge machinery; they also have a staff of experts who understand the nuances of welding rigs. This specialized expertise includes the finer points of rig upkeep and operation as well as the particular welding methods that optimize these rigs’ accuracy and efficiency.

In the dynamic world of welding, the demand for precision and reliability has led to the rise of specialized services. Among these, rig welding services stand out as a beacon of excellence, offering unique advantages that set it apart. If you’re in the market for top-notch welding solutions, read on to discover the top 8 reasons why rig welding services should be your ultimate choice.

The extensive knowledge that welding rig specialists bring to the table guarantees that every project gains from their profound comprehension of the equipment’s capabilities and the best ways to use them. This knowledge ensures that customers receive not only excellent welding services but also advice and solutions made specifically to meet the needs of their particular projects.

Efficient Time Management

One of the things that sets rig welding services apart in the welding industry is their effective time management. These services are excellent at optimizing their workflows to produce dependable and timely results since they have a deep awareness of the value of time in project execution.

Rig welding services, with their fleet of specialized welding rigs and highly qualified personnel, maximize every facet of the welding process, reducing downtime and expediting project schedules. Rig welding services are the go-to option for people who want their welding tasks completed quickly and precisely because of their ability to work quickly without sacrificing quality. Clients not only obtain high-quality welds but also benefit from efficient project completion.

Cost-Effective Solutions

Rig welding services provide affordable solutions, dispelling the myth that specialized services are expensive. These services maximize resources and reduce downtime, giving you a great return on investment.

Quality Assurance and Compliance

The highest priorities for rig welding services are quality control and adherence to industry norms. These services provide welds that not only meet but frequently surpass expectations by following stringent quality control procedures, resulting in a dependable and long-lasting final product.

Innovation in Welding Technology

In the welding industry, innovation is essential to staying ahead of the curve. The newest welding technology is constantly being invested in by rig welding services, so they can provide innovative solutions that improve the caliber and productivity of their job.