Welding is a skill that requires precision, expertise, and the right set of tools. Welders play a vital role in manufacturing processes, joining metals together to create structures, machinery, and products. To excel in this field, it’s essential to equip yourself with the necessary tools that facilitate smooth and accurate welding operations.

Understanding the Role of Tools in Welding

Tools are the backbone of any welding job. They not only help in achieving precise welds but also ensure the safety of the welder. From basic safety gear to advanced welding machines, each tool serves a specific purpose in the welding process.

Essential Tools for Welders

Safety Gear

Safety should always be the top priority for welders. Essential safety gear includes:

- Welding Helmet: Protects the eyes and face from sparks, UV rays, and debris.

- Welding Gloves: Provide heat and burn protection for hands while welding.

- Welding Jacket: Shields the upper body from heat and sparks.

- Respirator: Filters out harmful fumes and particles.

- Steel-Toed Boots: Protect feet from heavy objects and hot materials.

Welding Machine

A welding machine is the heart of any welding operation. It generates the heat necessary to melt and fuse metals together. Depending on the job requirements, welders may use different types of welding machines, such as stick welders, MIG welders, and TIG welders.

Angle Grinder

An angle grinder is a versatile tool used for cutting, grinding, and polishing metal surfaces. It’s indispensable for cleaning welds, removing slag, and preparing metal surfaces for welding.

Clamps and Magnets

Clamps and magnets are essential for holding metal pieces in place during welding. They ensure proper alignment and prevent distortion or movement of the workpiece.

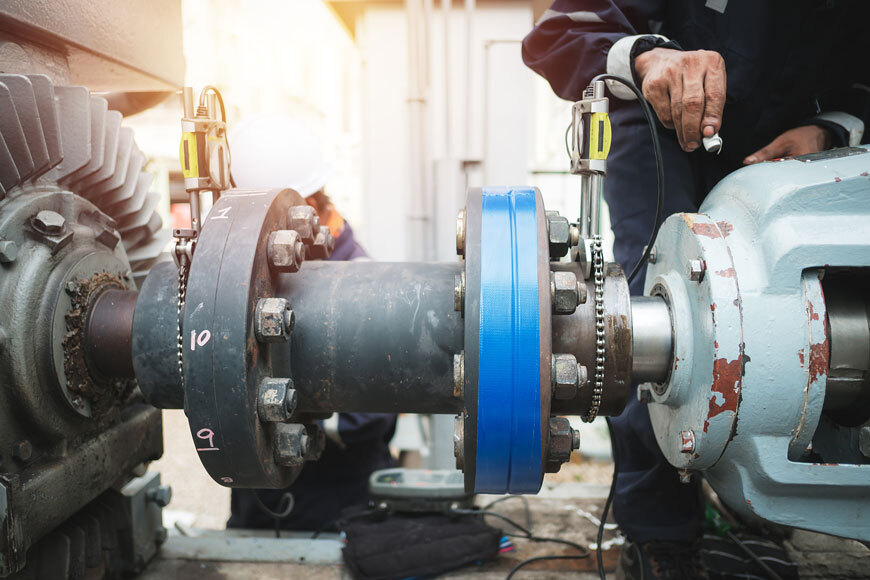

Specialized Tools for Advanced Welding Jobs

While basic tools are essential for everyday welding tasks, certain specialized tools are required for more advanced welding jobs:

Plasma Cutter

A plasma cutter is used to cut through electrically conductive materials quickly and accurately. It utilizes a high-velocity jet of ionized gas to melt and remove metal, making it ideal for cutting intricate shapes and thick metal plates.

Tungsten Inert Gas (TIG) Welder

TIG welding is known for its precision and clean welds. A TIG welder uses a non-consumable tungsten electrode to create the weld, along with a shielding gas to protect the weld area from atmospheric contamination.

Metal Cutting Saw

A metal cutting saw is used to make straight and angled cuts in metal workpieces. It’s essential for cutting large pieces of metal accurately and efficiently.

MIG Welder

MIG welding is a fast and versatile welding process that uses a consumable wire electrode and a shielding gas to create strong welds. MIG welders are commonly used in automotive, fabrication, and manufacturing industries.

Importance of Quality Tools in Welding

Investing in high-quality tools is crucial for achieving consistent and reliable welding results. Quality tools not only enhance productivity but also ensure the safety of the welder and the integrity of the welds.

How to Choose the Right Tools

When selecting welding tools, consider the following factors:

- Assessing Job Requirements: Determine the specific tools needed based on the type of welding job and materials involved.

- Considering Budget: Balance quality and cost to get the best value for your investment.

- Evaluating Brand Reputation and Warranty: Choose reputable brands known for manufacturing durable and reliable welding tools, and ensure they offer warranties for their products.

Having the right tools is essential for success in welding, especially in the manufacturing industry where precision and efficiency are paramount. By investing in quality tools and understanding their importance, welders can enhance their skills and achieve superior results in their welding jobs.

FAQs

Why is safety gear important for welders?

- Safety gear protects welders from heat, sparks, UV rays, and harmful fumes, reducing the risk of injuries and health hazards.

What factors should I consider when buying a welding machine?

- Consider factors such as the type of welding process, power source, duty cycle, and amperage range to choose the right welding machine for your needs.

Can I use the same welding machine for different types of welding processes?

- Some welding machines are versatile and can accommodate multiple welding processes, while others are designed for specific welding techniques.

How do I maintain my welding tools for optimal performance?

- Regular maintenance, including cleaning, lubrication, and calibration, is essential to ensure the longevity and performance of welding tools.

Where can I purchase welding tools and equipment?

- Welding tools and equipment are available at hardware stores, welding supply stores, and online retailers specializing in welding supplies.