Welcome to Weldit!

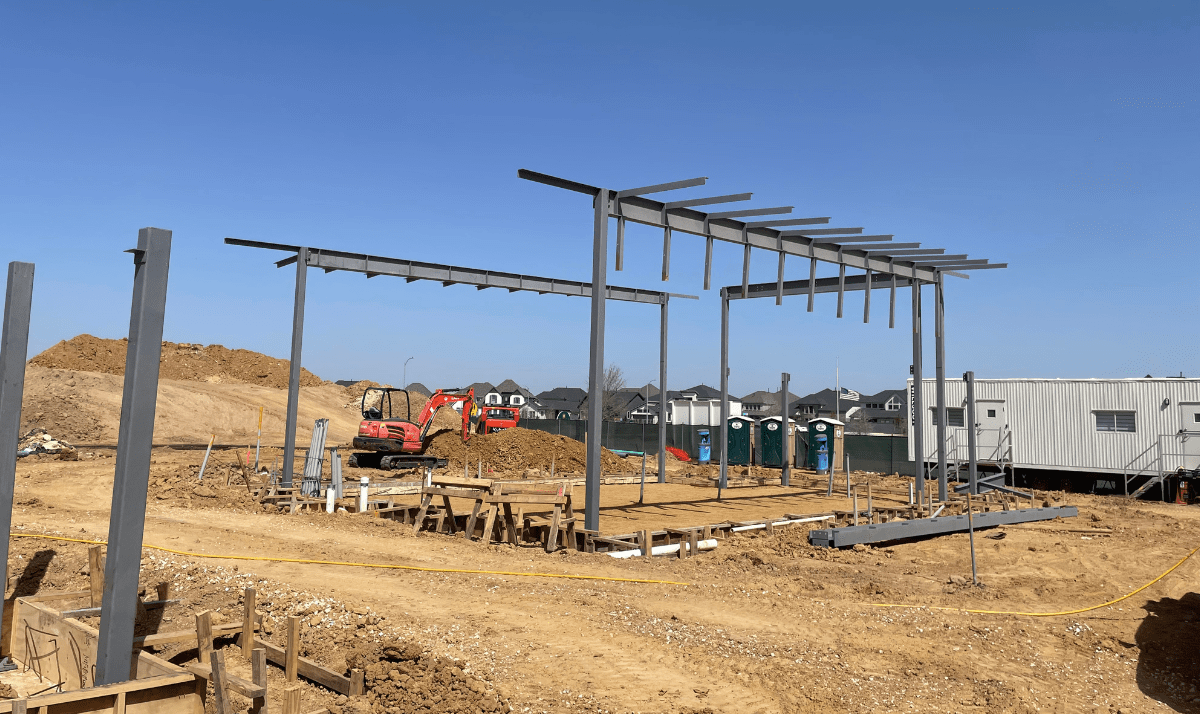

Professional Steel Erection Services in Houston, TX

WeldIT provides specialized industrial steel erection and heavy rigging services across Houston, TX. Our AWS-certified team specializes in high-precision structural framing and miscellaneous steel installation for commercial and manufacturing facilities.

What We Offer

Houston Steel Erection & Structural Solutions

WeldIT is Houston’s premier choice for robust structural steel erection, ranging from small custom shops to complex commercial strip centers. Our team specializes in the assembly and installation of heavy-duty framing, ensuring every project meets strict engineering standards and local Houston building codes.

Our Core Capabilities Include:

Structural Steel Erection: We provide precision assembly for warehouses, retail centers, and industrial facilities throughout Southeast Texas.

PEMB & Overhead Door Installation: As top-tier installers, we offer MBCI-certified services for seamless metal building erection and door installation in one streamlined process.

Mezzanine Steel Erection: Our certified mezzanine installers help businesses expand their commercial and residential spaces safely and efficiently.

- Custom Miscellaneous Steel: We fabricate and install essential secondary steel components, including safety handrails, guardrails, bollards, and custom stairs.

- Structural Integration: We ensure seamless integration between your main structural frame and miscellaneous steel elements like mezzanine supports or deck edges.

Work with an Experienced Houston Steel Erection Company

If you are looking for industry leaders in professional steel erection services, WeldIT should be your first choice. We bring years of hands-on experience to heavy structural steel projects and intricate architectural builds across the Houston area. Our mobile welding fleet and certified riggers ensure that your project is handled with precision from the first beam to the final bolt.

Core Pillars of Service

Strategic Erection Planning: We develop a comprehensive, site-specific plan for efficient project completion, ensuring your build stays on time and within budget.

Productivity-Driven Management: Our expert project management team optimizes every phase of the erection process to minimize costly delays and maximize on-site safety.

Transparent Communication: We maintain constant contact and provide scheduled site visits to keep you informed at every stage of the construction process.

Certified On-Site Welding: Our AWS-certified welders provide the structural integrity required for high-stakes industrial and commercial environments.

Our Professional Steel Erection Sequence

While structural frameworks can be erected in various ways depending on project specifications, WeldIT follows a rigorous, safety-first execution sequence to ensure every build is structurally sound and precisely aligned. Our process focuses on efficiency and engineering integrity for projects throughout the Houston area.

Step-by-Step Execution (Checklist)

Pre-Erection Inspection: Rigorous checking of site conditions and materials before work begins.

Column Erection: Precise placement and securing of the primary vertical supports.

Rafter Installation: Expert hoisting and attachment of horizontal roof beams.

Brace & Purlin Attachment: Securing the secondary structural members for lateral stability.

Frame Calibration: Fine-tuning the first and second frames for perfect vertical and horizontal alignment.

Complete Frame Installation: Finalizing the assembly of the primary structural skeleton.

Completion Check: A thorough intermediate review of all structural connections.

Covering & Finishing: Installation of exterior materials and final structural detailing.

- Final Inspection: A comprehensive safety and quality audit to ensure the project is ready for handover.

Our Expertise

Expert Steel Erection Across Diverse Industries

The structural steel erection industry serves critical sectors, including commercial construction, public infrastructure, and heavy manufacturing. At WeldIT, we provide specialized erection techniques tailored to the unique demands of each project in the Houston area.

This versatile technique involves the meticulous on-site assembly of steel components for various production and commercial projects. Our skilled Houston team ensures every piece is cautiously positioned and securely connected to guarantee the structural integrity of the complete framework.

This method utilizes high-strength bolts and nuts for connecting metal additives, offering flexibility for easier disassembly or future modifications. WeldIT combines engineering precision with speed to deliver reliable, sustainable structural solutions for modern commercial builds.

For initiatives demanding the highest structural integrity, we fuse metal additives through expert on-site welding. This technique offers superior energy and durability, making it the ideal choice for heavy industrial frameworks. Our AWS-certified weld crew ensures every connection is precise and incredibly strong.

HOW IT WORKS

From Concept to Creation: Our Steel Erection Procedure

Successfully executing a structural project requires following a series of critical, necessary steps. WeldIT follows a proven six-step procedure to ensure every steel structure we erect in Houston is built for maximum durability and safety.

Step 1

Foundation Preparation

First, we verify the foundation is level and engineered to support the structure's weight. Anchor bolts are then used to securely fasten the initial steel components to the base.Step 2

Structural Steel Delivery

Before erection begins, all components undergo a rigorous inspection for flaws or damage following transport to the Houston job site.Step 3

Assembly of Steel Components

Using precision cranes or hoists, our team assembles the primary framework on the ground before lifting sections into position to be permanently bolted or welded.Step 4

Installation of Secondary Steel

Once the primary skeleton is secure, we install essential secondary parts, including platforms, handrails, and industrial stairs, to finalize the structural construction.Step 5

Load Testing

Next, we conduct comprehensive load tests to ensure the structure can safely withstand the specific operational weight and environmental strain it will experience.Step 6

Inspection and Maintenance

To conclude the build, a final safety audit is performed. We also establish a routine maintenance schedule to ensure the structure remains secure and in optimal working order for years to come.Why Choose WeldIT for Steel Erection?

When it involves Steel Erection in Houston, WeldIT is the top choice for numerous motives. We combine local expertise with a commitment to excellence to ensure your structural project is a success from start to finish.

In Houston and the surrounding areas, we are a reputable business with a track record of success. We ensure that all projects are done with utmost professionalism while never sacrificing safety.

For us, honesty is the only policy. We strive to complete all projects with integrity, not just with our clients, but also our suppliers and contractors.

We commit ourselves to complete all projects within the timeline set with our clients. We use the best of technology and tools to ensure that all jobs are done quickly while also giving attention to details and ensuring everything is done correctly.

Frequently Asked Questions About Steel Erection

At WeldIT, we believe in transparency. Below are the answers to common questions regarding our Houston-based industrial rigging, structural welding, and safety protocols.

What is included in WeldIT’s steel erection services?

Do you provide specialized rigging for heavy structural components?

Are your welders certified for structural steel work?

Can you handle miscellaneous steel installation for existing commercial buildings?

How do you ensure safety on a steel erection job site?

Do you offer free estimates for Houston steel projects?

TESTIMONIAL

What Our Clients Say

"After partnering with them on multiple heavy structural builds, they've proven to be a top-tier choice for the Houston area. They deliver high-quality results while maintaining a strict focus on site safety and engineering precision. The team is professional, efficient, and always ready to tackle complex erection sequences."